Gaun Bedah SMS SS Mesin Kain Nonwoven Kualitas Tinggi PP Spunbond Jalur Produksi Kain Nonwoven

Aliran proses peralatan pamrosesan kain non-anyaman polipropilena

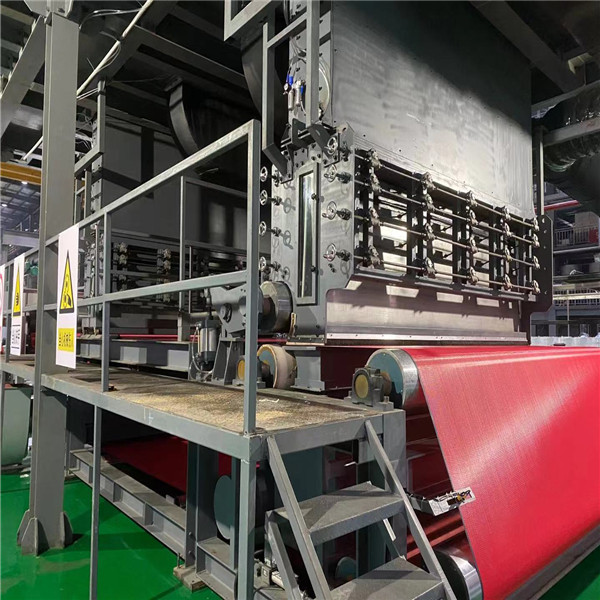

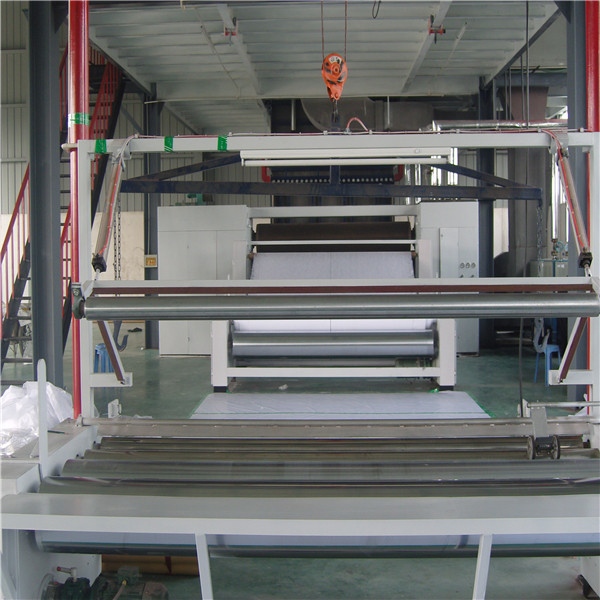

Mesin lan peralatan kain non-dirajut polipropilena: polimer (polipropilena + daur ulang) - sekrup suhu gedhe nyemprot pompa ekstrusi-filter-metering (pangiriman kuantitatif) -spinning (nyedhot munggah lan mudhun nyedhot ing inlet muter) —— Cooling —— Air doyo tarik —— Tirai jaring mbentuk —— Gulung munggah lan mudhun (pra penguatan) —— Guling panas (penguatan) pabrik gulung —— Gulung —— Geser kain kuwalik —— Timbangan lan kemasan —— Library produk rampung

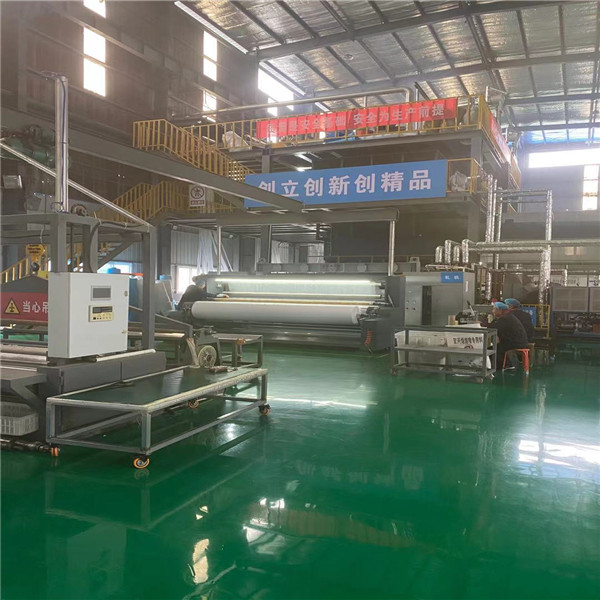

Tampilan aliran proses peralatan pamrosesan kain non-anyaman polipropilena

Model lini produksi tanpa tenunan

| SS (jembaré Prodnct) | 1600mm | 2400mm | 3200mm |

| Piranti | 29x13x10m | 30x14x10m | 32x15x10m |

| Kacepetan | 350m / menit | 350m / menit | 30m / menit |

| Bobot Gram | 10-150g / m2 | 10-150g / m2 | 10-150g / m2 |

| Hasil (Produk miturut 20g / M2) | 9-10T / Dina | 13-14T / Dina | 18-19T / Dina |

| ITEM | WIDTH sing EFEKTIF | GSM | OUTPUT TAHUNAN | POLA EMBOSSING |

| S | 1600MM | 8-200 | 1500T | Intan, oval, salib lan garis |

| S | 2400MM | 8-200 | 2400T | Intan, oval, salib lan garis |

| S | 3200MM | 8-200 | 3000T | Intan, oval, salib lan garis |

| SS | 1600MM | 10-200 | 2500T | Intan, oval, salib lan garis |

| SS | 2400MM | 10-200 | 3300T | Intan, oval, salib lan garis |

| SS | 3200MM | 10-200 | 5000T | Intan, oval, salib lan garis |

| SMS | 1600MM | 15-200 | 2750T | Intan lan oval |

| SMS | 2400MM | 15-200 | 3630T | Intan lan oval |

| SMS | 3200MM | 15-200 | 5500T | Intan lan oval |

Piranti pengolahan kain non-anyaman polipropilena

Kain spunbond non-tenunan

Bahan: PP polipropilena

Klasifikasi: SS, SSS

Werna: biru, putih, kuning

Aplikasi: Kesehatan lan kesehatan

Minangka jinis peralatan mekanik, lini produksi non-tenunan spunbond isih digunakake ing urip kita, nanging lini produksi non-tenunan spunbond uga butuh perawatan. Ayo goleki ringkes. Kaping pisanan, konten pangopènan utama lini produksi non-anyaman spunbond yaiku ngresiki, ngencengi, nyetel, pelumasan, lan anti korosi. Kapindho, departemen mekanik kanggo saben proyek kudu nindakake macem-macem tugas pangopènan miturut siklus sing ditemtokake miturut manual pangopènan lan prosedur pangopènan peralatan mekanik, nyuda tingkat nyandhang bagean, ngilangi bebaya kegagalan sing didhelikake, lan ngluwihi umur kerja mesin kasebut. Perawatan rutin dibutuhake, fokus ing reresik, pelumasan, inspeksi lan pengetatan. Pemeriksaan rutin lan pangopènan kudu ditindakake kaya sing dibutuhake sadurunge, sajrone lan sawise saben shift. Pangopènan rutin ditindakake kanthi mandiri dening operator mekanik, lan perawatan rutin dibutuhake kanthi rutin.

Iki minangka pungkasan editor babagan pangopènan lini produksi nonunun spunbond. Aku percaya kabeh ngerti manawa lini produksi nonunun spunbond wis umure dawa, mula lini produksi nonunun spunbond kudu dijaga lan dijaga. Nyambut gawe, mung kanthi nindakake proyek sing apik ing pangopènan bisa nambah panggunaan peralatan kasebut